Bottling & Packaging Plants For Milk & Fruit Juices

Ultra clean technology for cold filling of fresh milk, yoghurt and fresh juices using electronic flow-meter or weight filling systems, which ensure the maximum product protection suitable for filling fresh products and those requiring Extended Shelf Life.

Depending on the requirements, the process includes sterilization of the containers through the use of peracetic acid or hydrogen peroxide, an intermediate holding time, sterile water rinsing, non-contact filling and closing with previously sterilized closures.

All under protected environment with laminar flow Hepa filtration.

Semi and fully automatic solutions based on tailor made filling equipment, complemented with depalletizers, labelling machines, inline control devices and all available options for bottle handling/conveying and for end of line equipment.

Production Capacity: 1000 bottles/hour – 48000 bottles/hour

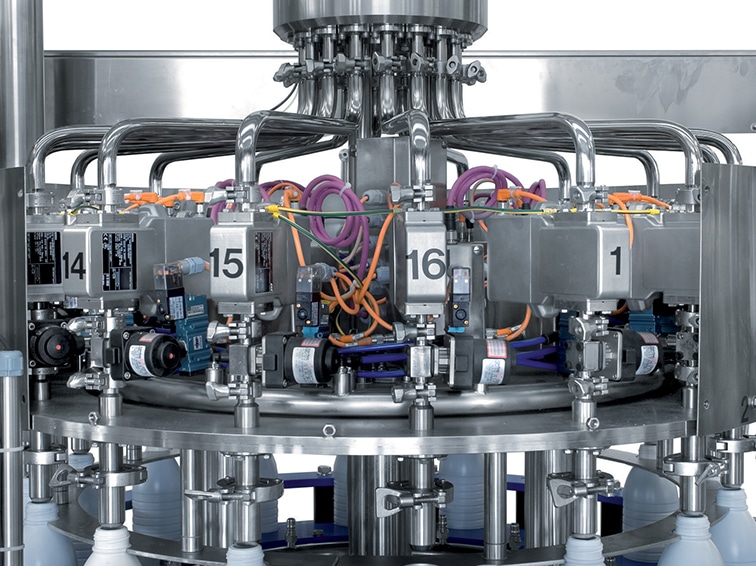

Filing Systems

Low vacuum-gravity filling systems are recommended for still, non-dense products such as for example still water, wine, alcoholic beverages (vodka, whiskey, brandy, etc), chemical products and generically any kind of flat non viscous liquids.

Various models of filling valves are available within this category, specifically designed to cater for the filling level requirements, bottle shape, neck shape and product.

Several optional features are available such as the “millimetric adjustment of the filling level” controlled directly from the user interface panel, air return outside the filling tank (to avoid the air from the bottles contaminating the product in the filler bowl), centralized level regulation and more.

Electronic flow meter filling system.

These systems assure maximum dosing precision and do not require any maintenance.

Thanks to the extremely small number of functional elements, the filling machine can be sanitized very easily and the Electronic Volumetric filling allows optimized filling under a microbiological profile.

The system works without pressure in the bottle and with a light positive pressure inside the filler bowl, allowing to process both high density and liquid products in containers of different materials.

The filling is controlled by the PLC that gives the go-ahead to start the filling when the sensor detects the presence of the bottles.

The electronic dosing devices with mass or magnetic flow meters show that the preset filling volume has been reached and control the closing of the valve, allowing a dosing precision of 0,2%.

As a result we obtain a precise volumetric filling and a microbiological safety.