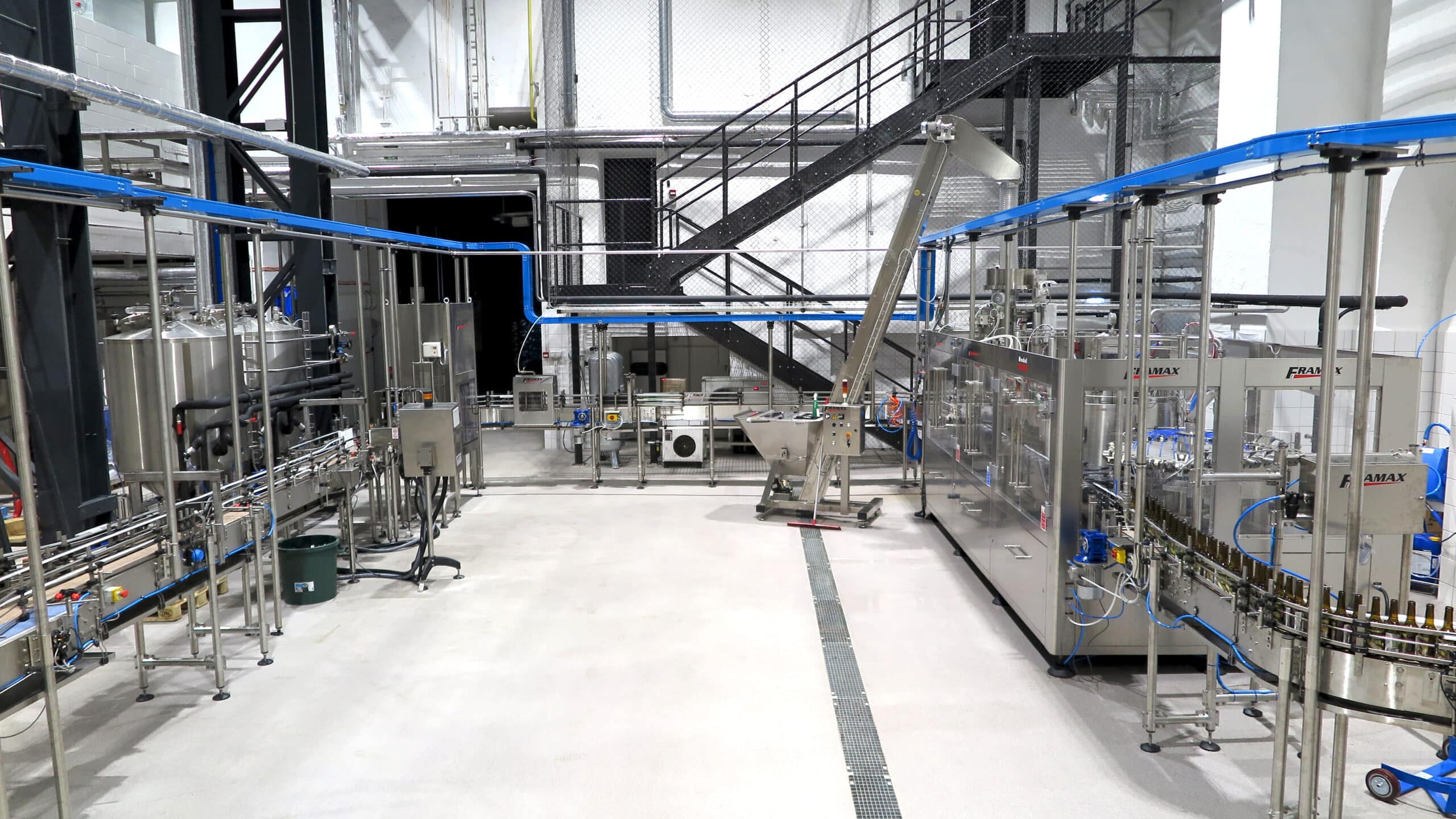

Bottling & Packaging Plants For Beer

Whilst keeping in mind the importance of caring about the product sensitivity to external contamination, Inpakt Beer filling machines make use of the traditional isobaric (counter-pressure) multi-pre-evacuation system for glass or aluminium bottles and specific filling systems designed to fill beer into PET, cans and kegs.

Depending on the beer type and customer needs the supply may include product treatment equipment such as flavour mixing, flash or tunnel pasteurisation, followed by the preferred labelling solution, packaging into cluster packs, cartons, shrink film and finally palletising.

Semi and fully automatic solutions based on custom made filling equipment, complemented with depalletizers, labelling machines, inline control devices and all available options for bottle handling/conveying and for end of line equipment.

Production Capacity: 1000 bottles/hour – 48000 bottles/hour

Filing Systems

Counter pressure filling systems suitable for filling all kinds of carbonated and still products such as carbonated water, soft drinks, beer, sparkling wines etc.

This is featured by various different types of filling valve designs, from the traditional mechanical counter-pressure, to the most sophisticated electro-pneumatic system.

The traditional mechanical counter-pressure valve enables to carry out several phases such as pressurization, CO2 injection, multiple pre-evacuation, levelling and snifting.

The usage of the electro-pneumatic valve allow to carry out the same functions, but it is completely controlled and programmable from the operator panel. This allows the most up-to date technology and flexibility which is necessary to obtain high quality results and reduced risk of contamination.

Low vacuum-gravity filling systems are recommended for still, non-dense products such as for example still water, wine, alcoholic beverages (vodka, whiskey, brandy, etc), chemical products and generically any kind of flat non viscous liquids.

Various models of filling valves are available within this category, specifically designed to cater for the filling level requirements, bottle shape, neck shape and product.

Several optional features are available such as the “millimetric adjustment of the filling level” controlled directly from the user interface panel, air return outside the filling tank (to avoid the air from the bottles contaminating the product in the filler bowl), centralized level regulation and more.

Electronic flow meter filling systems assure maximum dosing precision and do not require any maintenance.

Thanks to the extremely small number of functional elements, the filling machine can be sanitized very easily and the Electronic Volumetric filling allows optimized filling under a microbiological profile.

The system works without pressure in the bottle and with a light positive pressure inside the filler bowl, allowing to process both high density and liquid products in containers of different materials.

The filling is controlled by the PLC that gives the go-ahead to start the filling when the sensor detects the presence of the bottles.

The electronic dosing devices with mass or magnetic flow meters show that the preset filling volume has been reached and control the closing of the valve, allowing a dosing precision of 0,2%.

As a result we obtain a precise volumetric filling and a microbiological safety.