Food & Canning

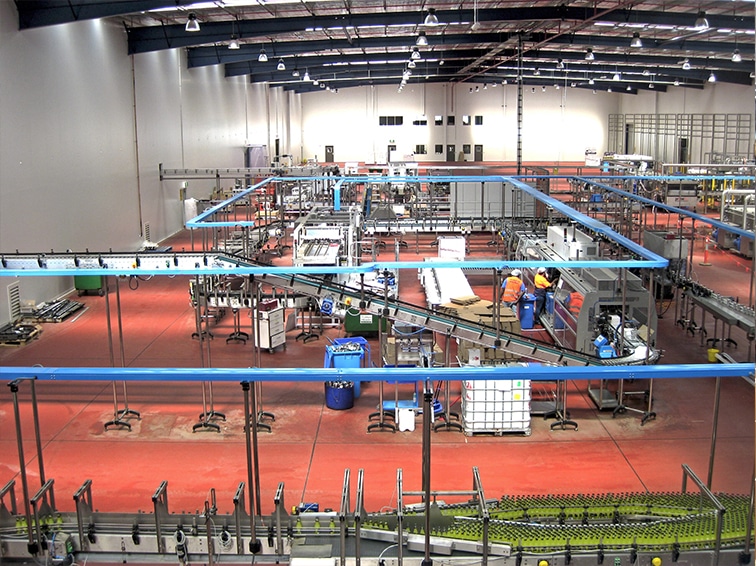

INPAKT manufactures and supplies a wide range of food preservation and canning equipment, as well as complete plants. Our plants and machines are used for the canning and preserving of meat, fish, jams, sauces, vegetables, ready meals, and more. INPAKT machines are reliable, durable, and precise, made with cutting-edge components and materials. Because each client has varying needs, we offer completely customised systems.

We have a strong focus on providing excellent service and customer satisfaction. Our team takes time to get to know our clients and their specific needs so that we can offer them a highly effective canning solution.

Our complete plants, innovative machines, and technology cater towards:

- Juices, concentrates, and purees

- Sauces

- Tomato paste

- Baby food

- UHT Milk

- Canned fruit

- Jams

Diced fruits and vegetables

Fruit bases for yoghurt & bakery

Jam

NFC & freshly squeezed juices

Reconstituted juice and milk

Ketchup

Our Processing Lines

INPAKT provides vegetable, salad, and fruit processing lines. These innovative processing lines are made up of sorting and select machinery, washing equipment, conveyors for dewatering and drying, centrifuging equipment, as well as specialised dosing and filling conveyors.

Vegetable processing line

Sorting-Select-Cutting, Washing Machinery, Centrifuging, Dewatering and Drying, Conveyors & Special Machinery.

Salad processing line

Sorting-Select-Cutting, Washing Machinery, Centrifuging, Dewatering and Drying, Dosing and Filling, Conveyors & Special Machinery.

Fruit processing line

Sorting-Select-Cutting, Washing Machinery, Centrifuging, Dewatering and Drying, Dosing and Filling & Conveyors & Special Machinery.

Pie Filling Machine

Our automatic pie filling machines have the ability to fill dough pockets with a variety of popular fillings, making for delicious pies or calzones.

Savoury

Our automatic savoury machines are ideal for the production of pastry products such as pizzas and Focaccia. The machine focuses on giving you maximum control over the specifications of your desired pastry product.

Confectionery

Our machines can be used for producing and filling cookies and biscuits so that they can have jam, icing fillers etc. The machines consist of filling feeders, moulders, cutters, and rounders. You are also able to create custom crusts and 3D shapes to set your product apart.

Frozen Foods

The frozen food industry is massive. Our frozen food plants are ideal for forming and filling frozen food products such as dumplings, ravioli, and more. You can completely customise your moulds and enjoy effective mass production.

Other Products

Spring Rolls, Doughnuts, Energy Bars, Bread Rolls, Samoosas, Cakes, Flatbread, Croquettes, Waffles, Bagels, and more.

Confectionery

Inpakt, together with our OEM partners supply lines for candy, toffee and wafer stick manufacture, sweet wrapping machines, chocolate moulding lines, sweet forming machines and others.

Confectionery Equipment

All INPAKT’s confectionery equipment is manufactured in line with all industry standards and regulations. Our confectionery equipment includes machines such as cooling tunnels, filling depositors, and enrobing machines. We provide everything you need for a full production line.

Wafer production

INPAKT provides wafer lines, wafer ovens, wafer coolers, and more. Our wafer stick production lines allow you to produce as many as 12,000 pieces in each hour. Sizes can vary greatly, with diameters up to 20mm and lengths up to 200mm.

Toffee-making equipment

We provide everything that you may need for toffee-making, including copper boilers, batch rollers, wrapping toffee lines, and more, allowing you to create a diverse range of toffees.

Chocolate manufacturing equipment

INPAKT offers all the equipment that you may need for manufacturing chocolate products and praline sweets. The equipment that we have available includes enrobers, cooling tunnels, aerators, coating bowls and more.

Cookie manufacturing equipment

Our rotor-forming equipment is ideal for the production of biscuits and cookies. We also supply cake machines, dough mixers, and ovens.

Confectionery wrapping and

packing machines

We supply a huge range of confectionery

wrapping and packing machines from

well-known manufacturers. Below is a small selection.

Wrapping machines

We supply packing and wrapping machines for soft candies, hard candies, chocolates, and more.

Food Canning

INPAKT provides vegetable, salad, and fruit processing lines. These innovative processing lines are made up of sorting and select machinery, washing equipment, conveyors for dewatering and drying, centrifuging equipment, as well as specialised dosing and filling conveyors.

Vegetable Canning Lines

Canned vegetables are a pantry essential, and can be found in almost every household. The integrity of canned vegetable products relies heavily on the production process and the quality of the equipment involved. It is important that the machines that you have on your production line can handle a variety of types of cans, and are durable and reliable.

Here at INPAKT, we offer high quality canning machines that are ideal for preserving a range of different types of vegetables.

Soup Canning Lines

Canned soup is probably one of the most popular and iconic canned products in the world, with dozens of different types of canned soups being available in your local grocery store. INPAKT offers soup canning lines that have a focus of hygiene, reliability, and control over specifications.

Meat Canning Lines

Canned meat is a convenient and affordable way of storing meat. Products such as corned beef and canned Vienna sausages are popular throughout the world. The most important thing about meat canning lines should always be hygiene and food safety. Our machines ensure minimal in-can oxygen levels for reliable preservation.

Fish Canning Lines

Tinned tuna is a staple for families and their pet cats alike, and tinned fish in general is a popular item on every grocery list. The equipment that we offer at INPAKT ensures sterilisation through high pressure steam facilities, and double seamed seals.

Tomato Canning Lines

The tomato is quite possibly the most versatile vegetable in the world, and canned tomato products include purees, sauces, diced tomatoes and whole tomatoes. It is very important that canning solutions maintain the nutritional integrity of the tomato product. Our machinery and vacuum seamers ensure that you are able to provide a high-quality end-product.

Filling Systems

Counter pressure filling systems suitable for filling all kinds of carbonated and still products such as carbonated water, soft drinks, beer, etc.

This is featured by various different types of filling valve designs, from the traditional mechanical counter-pressure, to the most sophisticated electro-pneumatic system.

The traditional mechanical counter-pressure valve enables to carry out several phases such as pressurization, CO2 injection, multiple pre-evacuation, levelling and snifting.

The usage of the electro-pneumatic valve allow to carry out the same functions, but it is completely controlled and programmable from the operator panel. This allows the most up-to date technology and flexibility which is necessary to obtain high quality results and reduced risk of contamination.

Low vacuum-gravity filling systems are recommended for still, non-dense products such as for example still water, wine, alcoholic beverages (vodka, whiskey, brandy, etc), chemical products and generically any kind of flat non viscous liquids.

Various models of filling valves are available within this category, specifically designed to cater for the filling level requirements, bottle shape, neck shape and product.

Several optional features are available such as the “millimetric adjustment of the filling level” controlled directly from the user interface panel, air return outside the filling tank (to avoid the air from the bottles contaminating the product in the filler bowl), centralized level regulation and more.

Electronic flow meter filling system.

These systems assure maximum dosing precision and do not require any maintenance.

Thanks to the extremely small number of functional elements, the filling machine can be sanitized very easily and the Electronic Volumetric filling allows optimized filling under a microbiological profile.

The system works without pressure in the bottle and with a light positive pressure inside the filler bowl, allowing to process both high density and liquid products in containers of different materials.

The filling is controlled by the PLC that gives the go-ahead to start the filling when the sensor detects the presence of the bottles.

The electronic dosing devices with mass or magnetic flow meters show that the preset filling volume has been reached and control the closing of the valve, allowing a dosing precision of 0,2%.

As a result we obtain a precise volumetric filling and a microbiological safety.

Volumetric (or piston) filling system guarantees that the container is filled with an exact quantity of product, having a maximum tolerance of +/- 1,5 cc using 1 litre cylinders.

This result is obtained regardless of the product’s thickness and of the differences in actual capacity between containers of the same type and size.

Therefore piston filling is the correct choice for applications where accuracy of actual volume contained in the bottles is important, or in case of filling dense products into plastic containers.

The filling system consists in two steps: during suction, the product passes from the tank to the metering chamber through a three-way valve which measures the product thanks to its piston-based operating principle, according to a preset quantity.

To empty the chamber, the three-way valves activates a pneumatic valve controlling the piston: the product is pushed out of the cylinder into the container.

It is possible to adjust the filling speed in the top portion of the container, where the neck must be filled slowly to prevent foaming or spillage.

Net weight filling system is used for various types of still products including thick and viscous liquids, such as vegetable oils, detergents, liquid soaps, etc into containers of any kind including soft plastic material such as PET or HDPE bottles.

The advantage of this system is that is very gentle on the product and allows extremely precise net weight measurement, regardless of the empty container weight variation.

High Vacuum filling is used for thick and viscous liquids, such as vegetable oils, syrups, sauces, etc into containers which are resistant to vacuum, such as glass bottles.

As opposed to the gravity or low vacuum system, the filling takes place by creating a vacuum inside the bottle through a separate channel, allowing the product to flow from the filling tank more easily.

At the end of the filling process, once the desired level has been reached, any excess product is collected into a dedicated reservoir on the ground and sent back to the main tank or managed according to the customer’s requirement.

The intensity of the vacuum is adjustable to suit the product density and the production speed.

Positive Pressure filling system is used for thick and viscous liquids, such as vegetable oils, syrups, sauces, etc into containers of any kind including soft plastic material such as PET bottles.

As opposed to the gravity or low vacuum system, the filling takes place by creating a positive pressure inside the filler bowl, allowing the product to flow from the filling tank to the containers more easily.

Hot filling system suitable for juices and isotonic beverages.

The principle of operation is similar to the gravity-low vacuum system, however the machine and its filling valves are designed to allow product recirculation in the tank and in the filling valves themselves in order to keep the constant filling temperature even in the eventuality of a machine stop.

With the hot fill technology it is possible to fill up to 90°C, guaranteeing a constant filling temperature and filling level accuracy.