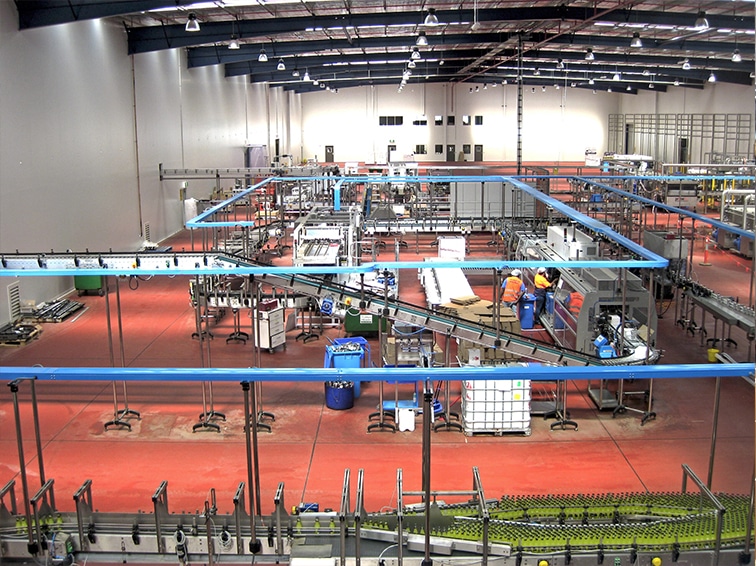

Conveyor Technology

INPAKT offers a comprehensive range of conveyor technologies for various industries

Conveyors

Our range of conveyors includes equipment such as chain conveyors, shuttles, lifts, vibration conveyors, roller conveyors, belt conveyors, and more. We create customised solutions based on our clients’ specific needs.

Pallet Conveyors

Our pallet conveyor systems ensure the safe transferral of pallets, cardboard, boxes, and heavy materials. The systems can include shuttles, lifts, transfers, turntables, to create a customised conveyor line, or multiple conveyor lines.

Automating any intralogistics processes

Gravity Roller Conveyor

Gravity roller conveyors are a popular choice for conveying crates, cartons, boxes, and more. This conveyor has the following features:

- Frame that can have its height adjusted, on articulated feet, and is powder-coated, and galvanised.

- High quality rollers (galvanised or plastic)

- Roller pitch in various sizes.

- Customised lengths

- Standard height of 800mm

- Can withstand a range of temperatures

- Stainless steel

Roller Conveyor Driven

The ideal conveying solution for boxes, crates, packages, and more. This conveyor solution has the following features:

- Frame that can have its height adjusted, on articulated feet, and is powder-coated, and galvanised.

- High quality rollers (galvanised or plastic)

- Roller pitch in various sizes.

- High quality gearmotors

- Customised lengths

- Standard height of 800mm

- Double sprocket, round belt, and poly-v belt drive options

- Can withstand a range of temperatures

- Options available for stainless steel, bidirectional, guiding bars. PLC automation, inverter drives

Belt Conveyor

The ideal conveying system for almost any product. This system has the following features:

- Durable, galvanised carrier with galvanised, powder-coated legs

- Adjustable height

- Articulated feet

- Compatible with a range of quality belts

- Drive pulley system using bearings

- Tensioning system for the return pulley system

- Galvanised rollers

- High quality gear motors, or drum motors

- Variety of module lengths available

- Standard height of 800mm

- Variety of conveying widths

- Conveying speeds: 0.2-2.5 m/sec

- Drive pulleys

- Can handle a range of temperatures

- Optional belt centralising, drum lagging, bidirectional, end stop, cantering.photocells, and guiding bars, inverter drive, and PLC control.

- Stainless steel for hygienic environments

Bulk Conveyor

The ideal solution for conveying bulk materials. This option has the following features:

- Galvanised and powder coated covers

- Sandblasted and powder coated beams and plates

- High quality belts

- Drive pulley consisting of rubber lagging, bearing housing, and clamping systems, with scrapper

- Return pulley system with tensioning bearings and rubber lagging, with v-scrapper

- Upper rollers and return rollers

- Self-centralising system

- High quality gearmotors

- Variety of lengths and widths available

- Withstand a variety of temperatures

- Options when it comes to bidirectional uses, transfer chutes, rollers, inverter drives, PLC control and more.

Pallet Roller Conveyor

Ideal heavy-duty conveyor system for boxes, and pallets. This system has the following features:

- Frame has transfer load of up to 2500kg

- Powder coated and galvanised frame

- Galvanised rollers with double sprockets

- High quality gearmotors

- Variety of lengths

- Standard conveying height of 400mm

- Conveying speeds: 0.2-0.5 m/sec

- Withstands a range of hot and cold temperatures

- Optional pallet guiding rings, bidirectional options, centering devices, photocells, stainless steel components, end stop, PLC controls, and inverter drives.

Pallet Chain Conveyor

The ideal, heavy duty conveyor option for the safe transfer of pallets. This option has the following features:

- Frame has transfer load of up to 2500kg

- Powder coated and galvanised frame

- High quality, low friction chain with automatic chain tensioners

- High quality gearmotors

- Variety of lengths available

- Standard conveying height of 400mm

- Conveying speeds: 0.1-0.4 m/sec

- Can withstand a range of hot and cold temperature

- Optional overlapping, bidirectional options, end stops, guiding bars, plate coverings, stainless steel components, photocells, inverter dives, PLC control, outside installation, and more.

Pallet Turntable Conveyor

This machine is ideal for changing the directions of products. It has the following features:

- Sandblasted, powder-coated frame

- Frame can handle loads of up to 2500kg

- Galvanised and powder-coated covers

- Slewing bearing

- High quality gearmotors

- Position monitoring system 9encoder optional)

- Standard conveying height of 400mm

- 3 turns in one minute

- Can handle hot and cold temperatures

- Optional outdoor installation, guiding bars, end stops, stainless steel frame, inverter drive, PLC control, photocells, and more.

90 Degrees Pallet Transfer Conveyor

This system allows you to change direction without ever having to rotate the pallet. The features of this system include:

- Sandblasted, powder-coated frame

- Frame can handle loads of up to 2500kg

- Galvanised rollers with double sprockets

- High quality, low friction chain, with automatic chain tensioners

- High quality gearmotors or hydraulic pistons

- Swing or parallel lifting options

- Variety of lengths available

- Standard conveying height of 400mm

- Conveying speeds: 0.1-0.4 m/sec

- Can withstand a diverse range of temperatures

- Options when it comes to multiple strands, bidirectional options, end stop, photocells, guiding bars, plates and covers, PLC, inverter drive, and more.

Pallet Lift Conveyor

Ideal for the vertical transporting and lifting of pallets. This system has the following features:

- Load capacities of between 500kg to 2500kg.

- Heavy duty frame

- Powder coated, sandblasted beams and plates

- Smooth rollers

- Pneumatic, gearmotors or hydraulic systems (all with different lifting capabilities)

- Variety of conveyor lengths

- Standard conveying height of 400mm

- Withstand a range of temperatures

- Optional extras for safety equipment, photocells, stainless steel components, inverter drives, and PLC control system.

Pallet Shuttle Conveyor

This system is ideal for the transfer of pallets over longer distances. It can also be used to connect systems. The features include:

- Load capacity of up to 2500kg

- Sandblasted and powder-coated frame

- Galvanised and powder-coated covers

- Compatible with chain conveyors or roller conveyors

- High quality gearmotors

- Positioning monitor (encoder optional)

- Effective guiding system with grooved rollers

- Standard conveying height of 400mm

- Speed: maximum 0.5m/sec

- Working conditions can be hot or cold

- Optional extras include end stops, guiding bars, PLC control, inverter driver, photocells, outdoor installation, and more.

Filling Systems

Counter pressure filling systems suitable for filling all kinds of carbonated and still products such as carbonated water, soft drinks, beer, etc.

This is featured by various different types of filling valve designs, from the traditional mechanical counter-pressure, to the most sophisticated electro-pneumatic system.

The traditional mechanical counter-pressure valve enables to carry out several phases such as pressurization, CO2 injection, multiple pre-evacuation, levelling and snifting.

The usage of the electro-pneumatic valve allow to carry out the same functions, but it is completely controlled and programmable from the operator panel. This allows the most up-to date technology and flexibility which is necessary to obtain high quality results and reduced risk of contamination.

Low vacuum-gravity filling systems are recommended for still, non-dense products such as for example still water, wine, alcoholic beverages (vodka, whiskey, brandy, etc), chemical products and generically any kind of flat non viscous liquids.

Various models of filling valves are available within this category, specifically designed to cater for the filling level requirements, bottle shape, neck shape and product.

Several optional features are available such as the “millimetric adjustment of the filling level” controlled directly from the user interface panel, air return outside the filling tank (to avoid the air from the bottles contaminating the product in the filler bowl), centralized level regulation and more.

Electronic flow meter filling system.

These systems assure maximum dosing precision and do not require any maintenance.

Thanks to the extremely small number of functional elements, the filling machine can be sanitized very easily and the Electronic Volumetric filling allows optimized filling under a microbiological profile.

The system works without pressure in the bottle and with a light positive pressure inside the filler bowl, allowing to process both high density and liquid products in containers of different materials.

The filling is controlled by the PLC that gives the go-ahead to start the filling when the sensor detects the presence of the bottles.

The electronic dosing devices with mass or magnetic flow meters show that the preset filling volume has been reached and control the closing of the valve, allowing a dosing precision of 0,2%.

As a result we obtain a precise volumetric filling and a microbiological safety.

Volumetric (or piston) filling system guarantees that the container is filled with an exact quantity of product, having a maximum tolerance of +/- 1,5 cc using 1 litre cylinders.

This result is obtained regardless of the product’s thickness and of the differences in actual capacity between containers of the same type and size.

Therefore piston filling is the correct choice for applications where accuracy of actual volume contained in the bottles is important, or in case of filling dense products into plastic containers.

The filling system consists in two steps: during suction, the product passes from the tank to the metering chamber through a three-way valve which measures the product thanks to its piston-based operating principle, according to a preset quantity.

To empty the chamber, the three-way valves activates a pneumatic valve controlling the piston: the product is pushed out of the cylinder into the container.

It is possible to adjust the filling speed in the top portion of the container, where the neck must be filled slowly to prevent foaming or spillage.

Net weight filling system is used for various types of still products including thick and viscous liquids, such as vegetable oils, detergents, liquid soaps, etc into containers of any kind including soft plastic material such as PET or HDPE bottles.

The advantage of this system is that is very gentle on the product and allows extremely precise net weight measurement, regardless of the empty container weight variation.

High Vacuum filling is used for thick and viscous liquids, such as vegetable oils, syrups, sauces, etc into containers which are resistant to vacuum, such as glass bottles.

As opposed to the gravity or low vacuum system, the filling takes place by creating a vacuum inside the bottle through a separate channel, allowing the product to flow from the filling tank more easily.

At the end of the filling process, once the desired level has been reached, any excess product is collected into a dedicated reservoir on the ground and sent back to the main tank or managed according to the customer’s requirement.

The intensity of the vacuum is adjustable to suit the product density and the production speed.

Positive Pressure filling system is used for thick and viscous liquids, such as vegetable oils, syrups, sauces, etc into containers of any kind including soft plastic material such as PET bottles.

As opposed to the gravity or low vacuum system, the filling takes place by creating a positive pressure inside the filler bowl, allowing the product to flow from the filling tank to the containers more easily.

Hot filling system suitable for juices and isotonic beverages.

The principle of operation is similar to the gravity-low vacuum system, however the machine and its filling valves are designed to allow product recirculation in the tank and in the filling valves themselves in order to keep the constant filling temperature even in the eventuality of a machine stop.

With the hot fill technology it is possible to fill up to 90°C, guaranteeing a constant filling temperature and filling level accuracy.