Carbonated & Still Filling Lines for Canned Beverages

Complete projects including syrup production, high precision flavour dosing & mixing systems for the production of soft drinks, alcoholic mix beverages, energy drinks and similar products packaged into PET, Glass & Cans.

Inpakt supplies customized solutions to cater for each of the above-mentioned product process requirements, such as counter-pressure filling, pasteurising or warming, labelling using an extensive range of the most modern and cost saving labelling techniques, followed by packaging loose or clustered packs into boxes or shrink-wrapped bundles, etc.

Sparkling soft drinks and still beverages

Semi and fully automatic solutions based on tailor made filling equipment, complemented with depalletizers, labelling machines, inline control devices and all available options for bottle handling/conveying and for end of line equipment.

Production Capacity: 1000 bottles/hour – 48000 bottles/hour

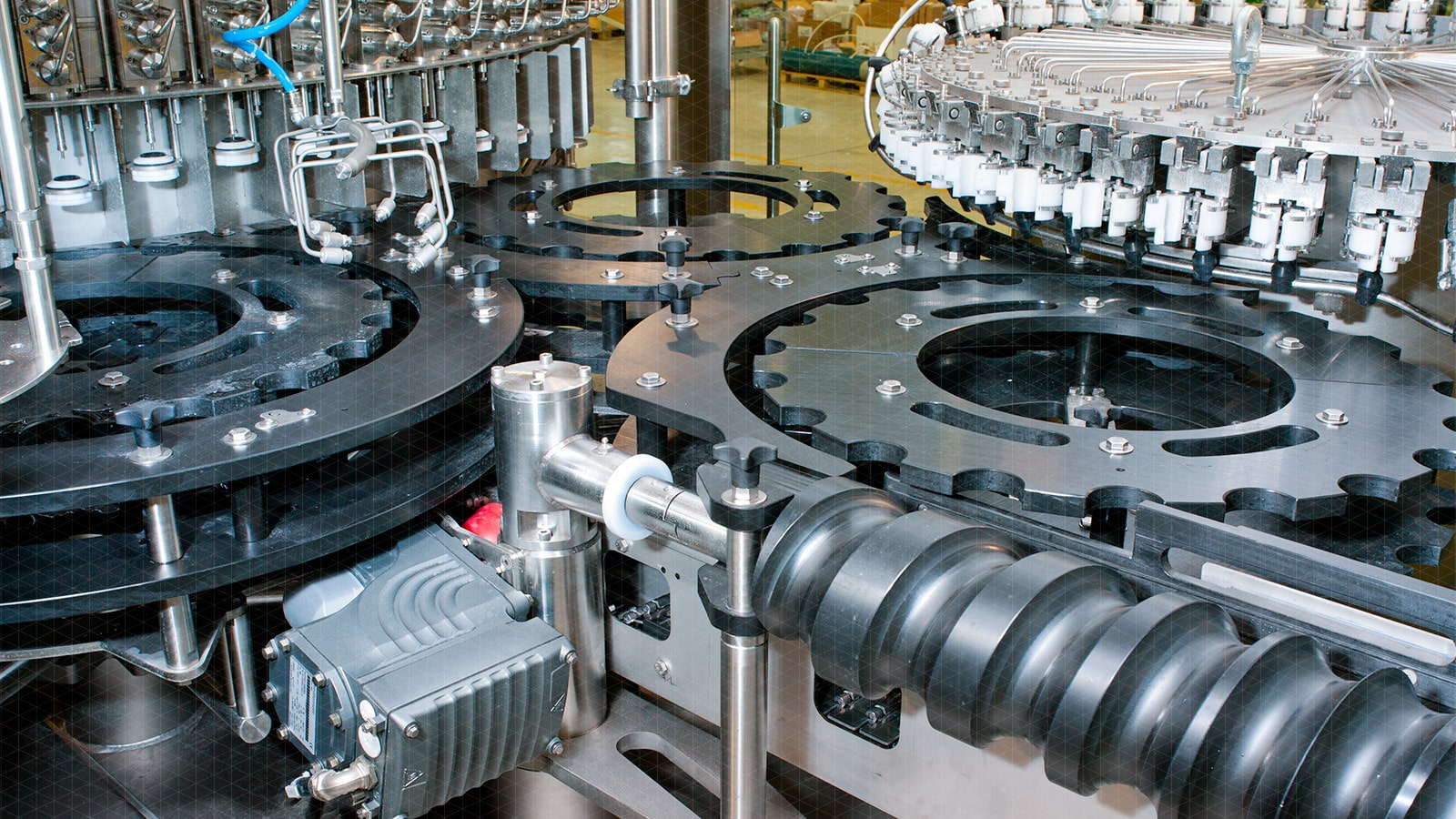

Filing Systems

Counter pressure filling systems suitable for filling all kinds of carbonated and still products such as carbonated water, soft drinks, beer, etc.

This is featured by various different types of filling valve designs, from the traditional mechanical counter-pressure, to the most sophisticated electro-pneumatic system.

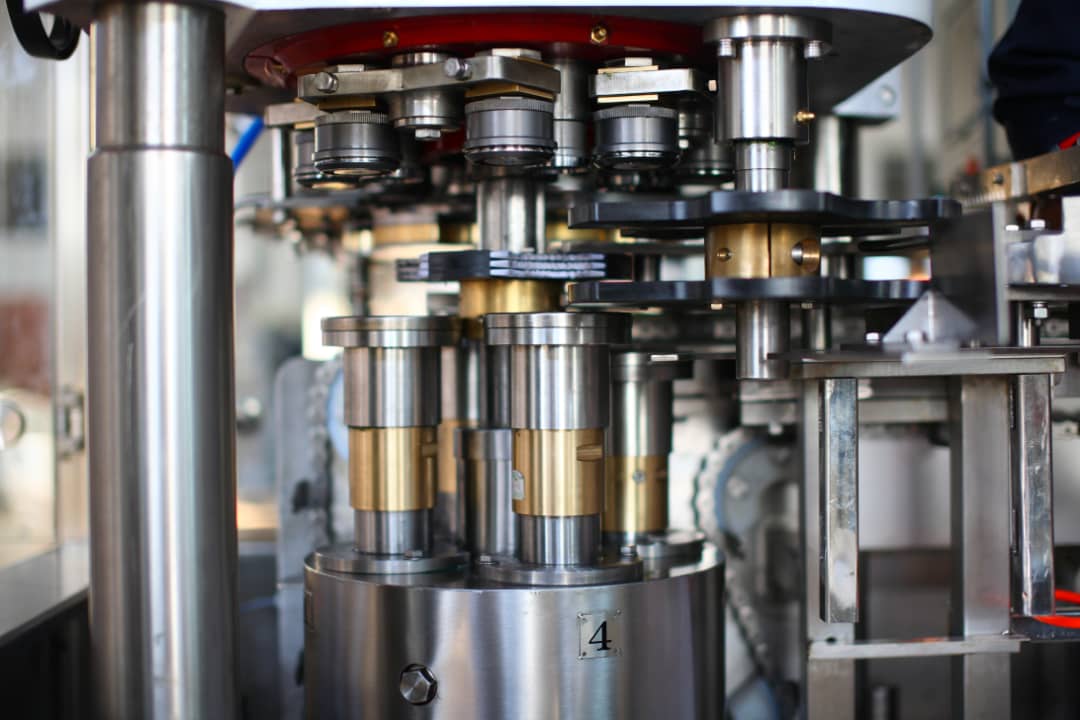

The traditional mechanical counter-pressure valve enables to carry out several phases such as pressurization, CO2 injection, multiple pre-evacuation, levelling and snifting.

The usage of the electro-pneumatic valve allow to carry out the same functions, but it is completely controlled and programmable from the operator panel. This allows the most up-to date technology and flexibility which is necessary to obtain high quality results and reduced risk of contamination.